Campaign for Real Recycling

Reprocessing Adds Value

New Zealand re-processing industries use recyclables collected at the kerbside as feedstock to produce new products. These include cardboard, glass bottles and a wide range of plastic goods including matting, slip-sheets, and water tanks. This creates jobs and generates export earnings at the same time. It reduces our dependence on virgin materials (imports) and improves our environmental performance. It is a good fit with the 100% Pure NZ branding.

A Short History of Kerbside Recycling

Kerbside recycling was introduced in New Zealand in the early 1990’s using a crate based system with kerbside sorting. Recycling is now common practice, and we are seeing new generation collection systems that rely on mechanised collection and sorting systems. This shift to capital intensive, mechanical systems is a global trend. These systems simplify the collection phase by collecting everything in one container and no sorting is done at the kerb. This is known as a commingled collection system.

What is “Commingled” or “Single Stream Recycling?”

All recyclables (paper, plastic, glass, steel and aluminium cans) are collected in a single wheelie-bin, compacted and sorted later at a Materials Recovery Facility (MRF).

Understanding Commingled / Single Stream Recycling Systems

Commingled systems have two main parts, the collection phase and the sorting phase.

1. Commingled Collection The commingled collection methodology uses the same types of vehicles, bins and lifters that are used to collect rubbish, to collect our recycling. Householders are encouraged to put all their recycling into one large bin, a wheelie-bin. Bins are lifted into a truck using a one-armed bandit. No sorting gets done during the collection phase.Recyclables are compacted in the truck to maximise the volumes collected on each run and to increase transport efficiencies Compacting during collection increases the weight collected per load.This reduces the number of vehicles needed to service a given number of households and the number of trips to the MRF for off loading. Commingled collections have gained popularity as they are thought to be safer for the collection staff. It is also assumed that the net cost of recycling will be lower when the collection cost is lower.

2. Sorting Commingled RecyclingCommingled collections require a mechanised “Materials Recovery Facility” (MRF) for sorting out the recyclables. A MRF is a mechanised sorting system for separating recyclables; paper, cardboard, glass, plastics, cans and tins.These MRF systems vary in size and scale but they all have a series of conveyors with a range of equipment for separating materials. These can include screens, eddy current separators, and optical sorters.MRFs come with a high capital cost and high ongoing operating and maintenance costs. They use a lot of energy to run all the conveyors and complex equipment.A lot of recyclable material needs to flow through the system to cover the capital cost of investing in this hi tech equipment, so usually a MRF serves a large population base across a city, a district or a region.A MRF is thought to reduce the net cost of recycling as less labour is used in the process.

Understanding Kerbside Sort (Multiple Stream) Collections

Kerbside sort systems collect and sort the recycling in a very different way.

Understanding Kerbside Sort Recycling Systems

Kerbside sort systems also have two main parts, the collection phase and the sorting phase, but seems to get very different results.

- Kerbside Sort CollectionsThe kerbside sort methodology uses vehicles, bins and lifters that have been purpose built for collecting recycling. Householders are encouraged to separate their recycling at home. Different areas have different combinations of recyclables bundled together. Often cans and plastics go together in a crate with paper and card bundled separately. Sometimes glass goes in with the plastic and cans, sometimes it is kept separate.Recyclables are sorted at the kerbside, with different materials going into different truck compartments. Keeping recyclables separate reduces contamination and ensures high quality recyclables are available as feedstock for re-processors. Because a lot of the sorting is done during the collection phase, this can mean higher collection costs. This is usually offset by lower cost in the sorting phase.International evidence suggests that kerbside sort collections are not necessarily more dangerous than commingled ones, the risks are different. So long as the risks associated with both methods are effectively managed either system can be safely used.It is thought that separating recyclables at home helps householders become aware of what is and is not recyclable. This creates a feedback loop that helps people choose recyclable packaging and paper products. This leads to action that sees people reducing, reusing and recycling more over time.

- Sorting Kerbside Sort RecyclingKerbside sort collections provide semi sorted material to the processing facility.Some mechanical systems, like conveyors, will be used to help separate the material but people do a lot of the sorting work. These systems vary in size and scale but are generally low tech.Sorting systems for material that has been separated at source have low capital cost and low operating and maintenance costs. They also use a lot less energy. These low cost systems do not rely on high throughput, so they can be smaller and employ local people to do the sorting and baling work.Kerbside sort is thought to reduce the net cost of recycling once the sale of material has been taken into account. There is evidence that the net cost of recycling will be lower when the recycling system produces high quality recyclables for resale. It is easier to get high quality recyclables with a kerbside sort system.

Opinions are Changing

At first glance, many people thought the move to commingled recycling had a number of advantages. These included increased participation by households and reduced collection costs. However, significant disadvantages have started to appear and evidence from around the world shows that commingled or single stream recycling may not be as cost effective as it first seemed.

The rapid shift to commingled systems has had a direct impact on both the cost of recycling and our ability to recycle the materials collected. New Zealand re-processors have seen two trends emerge; first a decline in the quality of the material coming out of the sorting facilities and second a reduction in the total volume of recyclables suitable for re-processing in New Zealand.

Commingled collection systems that gather a range of different materials in one bag or bin, then compact them during collection could permanently undermine the environmental, social and financial benefits of recycling.

Some councils have shifted to the new commingled recycling methods before they have been proven to meet the needs of all the players in the recycling chain. This is a concern, as many of the contracts are long-term due to the high capital cost involved in setting up highly mechanised systems.

These contracts lock us all into a system that does not deliver the best outcomes for everybody. These contracts do not provide for flexibility over time as new evidence becomes available and opinions change.

What can we do?

Commingled collections are having an impact globally. If New Zealand wants to ensure quality recyclables are available for our New Zealand based re-processing industries, or if surplus recyclables are to be exported, we need to make sure these are quality. We need to support our own industries and safe guard our international reputation.

We can do this by:

- Becoming better informed

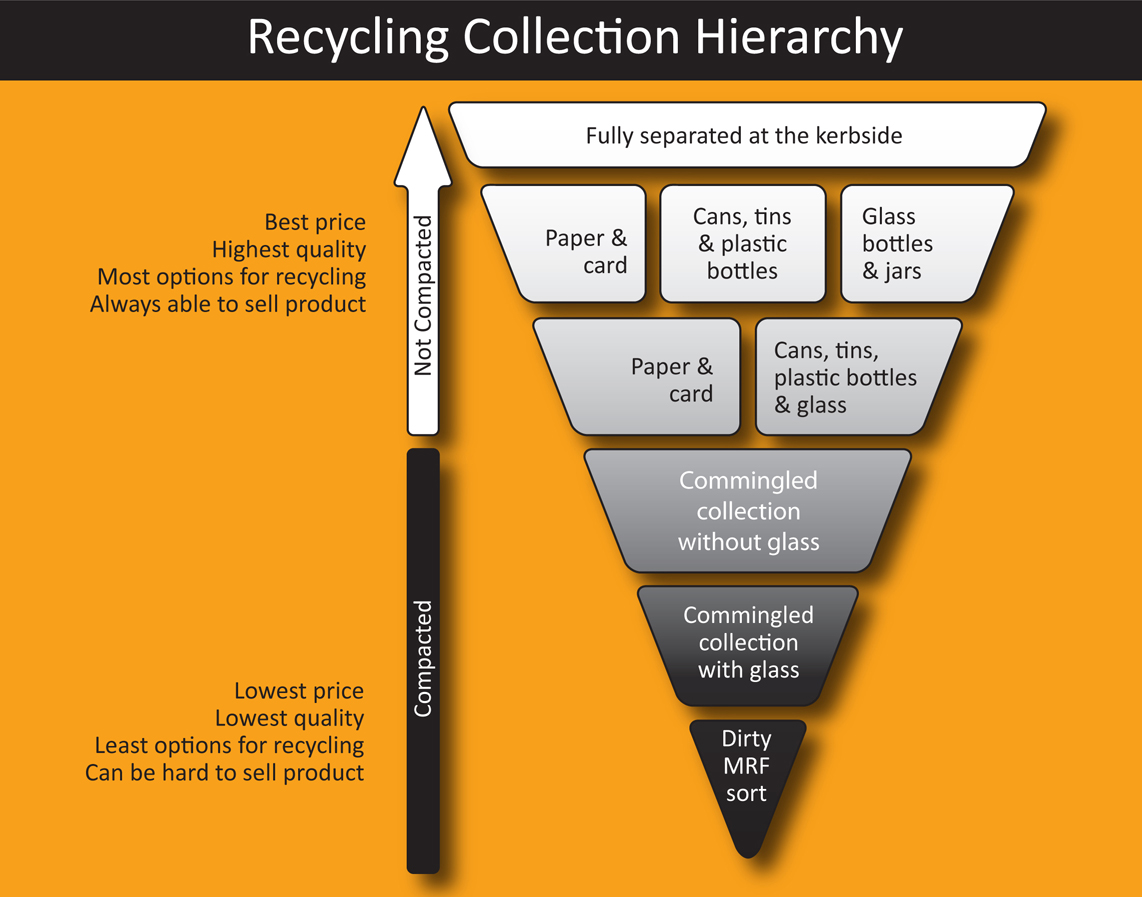

- Reviewing the recycling collection hierarchy for best practice

- Selecting a recycling service that is as high up the collection hierarchy as possible

- Assessing the real long-term costs of kerbside sort versus sorting at a MRF

To begin with people thought it was an either/or choice between crates with full kerbside sort and commingled collections with a regional MRF.

Some councils are starting to try different ways of collecting recycling. Palmerston North, Wellington and Dunedin have all decided to try systems that have glass collected separately. These hybrid systems could prove to be a workable compromise between the cost of the recycling system and the quality of material available for reprocessing.